Composite wires produced by infiltration of continuous CNT spun fibers with copper or aluminum can reduce the weight of conductors. An all-nanotube cable structure is possible for even more dramatic weight reduction.

CNT-based wire conductors and BNNT non-woven matt used as dielectric insulation in coaxial cables can both contribute to dramatically reducing the weight of electrical conductors. Lower energy usage has become a strong driving force for light weighting cables and for other replacements for copper or aluminum in applications such as aerospace and motor vehicles. Examples include improved operating range and time on station capabilities for aircraft, ability to carry larger payload, reduced CO2 emission for aircraft and reduced in-theater logistics for fuel management, as well as significant saving from greater fuel efficiency. Weight is also very important if the conductor must be accelerated as is the case in large traction motors where rotating heavy copper armatures contribute to losses as motors or generators start and stop. Another important area is high voltage power cables where not only size and weight but also mechanical properties are essential: a fatigue-resistant lightweight and compact cable capable of carrying very high currents would create a paradigm shift in the high voltage power line industry.

Features and Benefits

Marine environments and High Temperatures Applications:

CNT fibers have been reported to be structurally resistant to most strong acids, both oxidizing and reducing and even those containing halogens, which makes them perfect candidates for applications where metals fail due to corrosion. This is an important issue for aging aircraft and for Navy aircraft. Carbon nanotubes are also stable at temperatures up to ~400 °C. Aluminum cannot be used at these temperatures and copper is susceptible to creep and too weak for most uses. Examples include alternators or generators in contact with hot jet engine components or components operated near the ocean.

Applications:

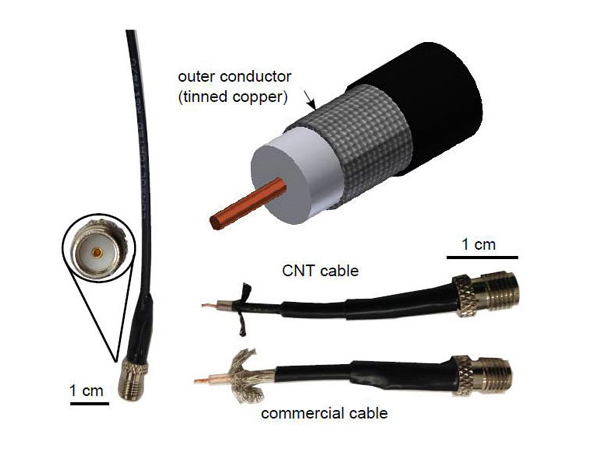

Components, including in particular coaxial cables, which will benefit from the low density, fatigue resistance and strength of the CNT composite wiring: powerlines, motor windings, aircraft wiring, wiring exposed to high temperatures, high current wiring under stress.