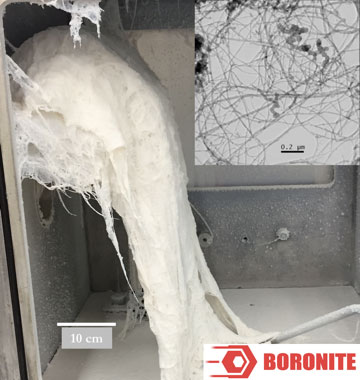

BNNTs

Boron nitride nanotubes are a revolutionary material with unique multifunctional properties and great commercial potential. Their electro-mechanical, thermal, shielding, and high fracture energy properties have the potential to revolutionize many aerospace and terrestrial applications. By significantly reducing weight, improving strength, and replacing multiple materials in each application, Boronite’s materials will have a major positive impact on efficiency and emissions.

BNNTs have a structure similar to their well-known carbon nanotube (CNT) counterparts, but with alternating boron and nitrogen atoms self-assembling into a nanoscale tube whose diameter may range from 1 to 20nm and whose length may vary from a few microns to millimeters. Due to their similar structure, BNNTs have the same phenomenal mechanical properties associated with CNTs, particularly their incredible mechanical strength and ability to be integrated into almost any shape. However, BNNTs offer additional, superior properties and characteristics when compared with CNTs, most notably:

- They exhibit much higher self-friction than CNTs, with the expectation of yielding much stronger yarns

- They maintain structural stability at temperatures up to 900°C in air, whereas CNTs are unstable above 400°C

- They are relatively inert to most acids and alkalis

- They are insulators but can be turned into semiconductors with a bandgap tunable by doping or external electric field

- They show outstanding electrical shielding ability

- They exhibit thermal transfer properties similar to CNTs (~1000 watts/m×K) but with electrically insulating characteristics

- They posess neutron radiation absorption and shielding properties provided by boron atoms in the structure

- They exhibit piezoelectric characteristics

- They are easily incorporated into matrices of a wide variety of other materials, including ceramics, polymers and metals

Superwire

Boronite, with funding through an Army Phase II SBIR, has developed advanced electrical conductor prototypes based on continuous CNT yarns. A 4-ft long, 1/4 in diameter SuperWire cable fabricated at Boronite and tested at an independent facility repeatably sustained currents in excess of 500 Amperes without degradation. The goals of our Superwire program are twofold:

1. Optimize the electrical properties of our continuously spun CNT yarn. Depending on their structure, CNTs can exhibit either semiconducting or metallic characteristics. When nanotubes are produced in high volume, they normally include a mixture of a wide range of semiconducting and metallic chiralities, which is detrimental to yarn properties. A major achievement of this phase of the program is to control the type of CNTs we produce in our reactors in order to spin yarns from predominantly metallic CNTs.

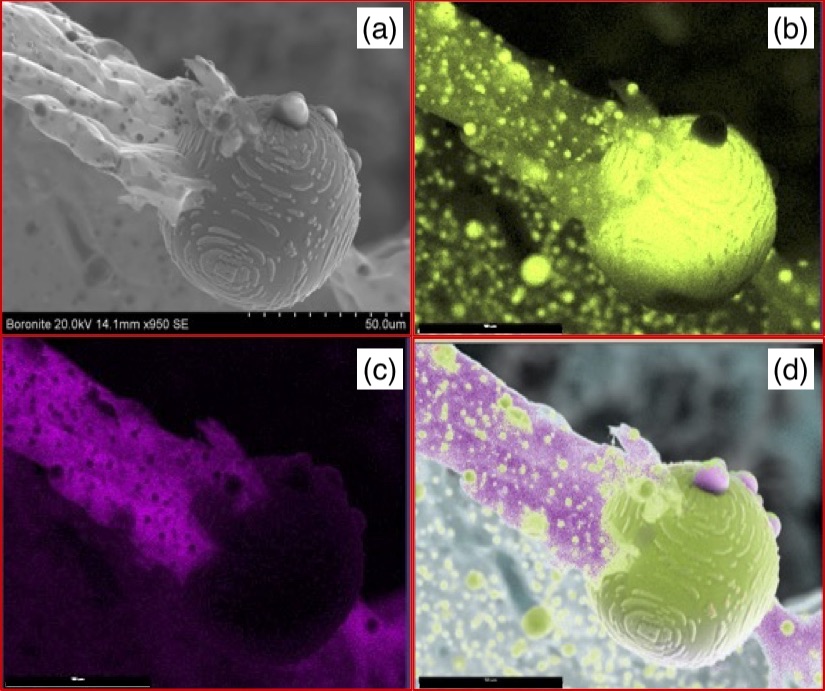

2. Infiltrate or coat the CNT yarn with aluminum or copper to create a novel class of continuously reinforced metal/CNT composite lightweight electrical conductors. Until now, CNT-reinforced metal composites have not been available due to the difficulties inherent in their production: molten copper will not wet carbon and aluminum will react to form carbides detrimental to the composite's properties. Our patent-pending technology enables wetting of CNTs by copper and alumninum, which results in strong interfacial bonding and better charge transfer between the metal matrix and CNT reinforcement. Scanning Electron Microscopy and Energy-Dispersive X-ray spectroscopy pictures below show examples of the metal infiltrating the CNT network.

SEM/EDS images showing infiltration of a CNT network by copper.

(a) SEM image; (b) Copper EDS image; (c) Carbon EDS image; (d) All elements image