Boron nitride nanotubes (BNNTs) are isoelectronic and isostructural with carbon nanotubes (CNTs), which are cylinders with diameters on the order of nanometers and lengths usually on the order of micrometers, but which may extend to millimeters or more. The carbon atoms in CNTs are substituted by alternating boron and nitrogen atoms in BNNTs. BNNTs were first synthesized by Alex Zettl in 19951 following theoretical predictions by Marvin Cohen2. They are one of the few advanced materials whose existence was predicted before discovery. However, the properties of BN nanotubes are very different from carbon nanotubes: whereas CNTs can be metallic or semiconducting depending on the rolling direction and radius, a BNNT is an electrical insulator with a bandgap between 5.5 and 5.9 eV. Unlike for CNTs, this bandgap can be tuned either by applying a bias voltage or by substituting carbon atoms in the BNNT structure, so that the lower bandgap limit can be extended to about 0.2 eV. The arrangement of alternating boron and nitrogen atoms gives BNNTs a corrugated surface and some degree of ionic bonding, so they attach more readily to other molecules and to themselves.

Examples of Boronite BNNT Formats

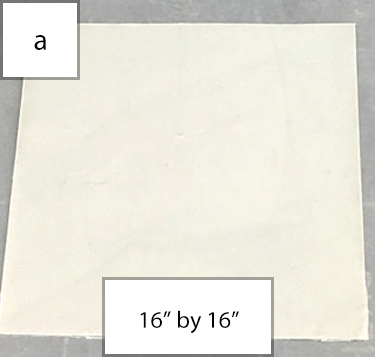

a. Pressed Panel

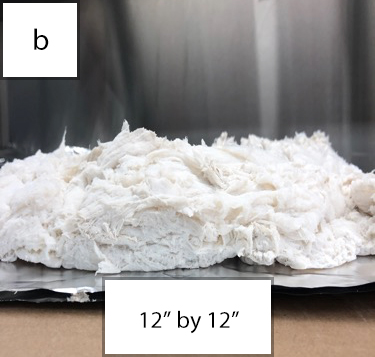

b. Top view of as harvested material

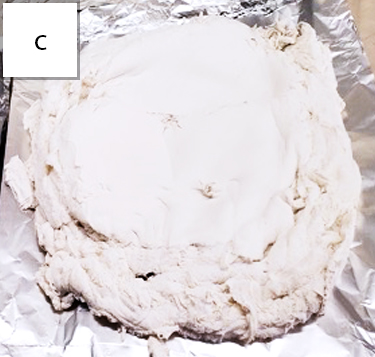

c. Side view of as harvested material

Suggested Applications and Properties

- Dielectric insulation at very low density.

- Radiation shielding for humans (fabrics for space suits or hazmat suits) and for protecting electronics.

- Used in composites to shield against other forms of radiation and for strengthening.

- Flame resistant in the air at very high temperatures.

- Thermally conductive and electrically insulative. Potential use in printed circuit boards for thermal management without risk of causing short circuit.

- Electrical and field emission can be tuned by doping with gold atoms.

- Bandgap can be engineered over a large range by adding carbon or by applying an electric field (field-effect transistors at room temperature).

- Variety of uses in the biomedical field as nanocarriers and as nano-transducers.

- Potential for use in multijunction solar cells.

Resources

1. N.G. Chopra, R.J. Luyken, K. Cherrey, V.H. Crespi, M.L. Cohen, S.G. Louie and A. Zettl, "Boron Nitride Nanotubes”, Science 269, pp. 966-967 (18 August 1995)

2. X. Blase, A. Rubio, S.G. Louie and M.L. Cohen, “Stability and Band Gap Constancy of Boron Nitride Nanotubes”, Europhys. Lett., 28 (5), pp. 335-340 (1994)

| PROPERTIES | APPLICATIONS | BNNT or CNT | COMMENTS |

|---|---|---|---|

| Strength and Modulus | Composites: Polymer matrix Metal matrix Tethers and cables Armor | Both | Flexibility allows 3D weaving Extraordinary resistance to fatigue BNNT yarns expected to be much stronger than CNT yarns due to higher friction forces between BNNTs High fracture toughness coupled with high modulus and strength suggest extraordinary armor performance at much lighter weight than Dyneema armor |

| High Temperature Oxidation Resistance | Ceramic composites or BN-BN | BNNT | Applications at temperatures of up to 900°C in air are possible without causing damage to the structure |

| Thermal Properties | Thermal conductors | Both | Thermal conductivity is generally above 1000 W/m•K for individual tubes but much lower (~40 to 60 W/m•K) for yarns and tapes |

| Radiation Shielding | Multifunctional (structural and shielding) and lightweight | BNNT | Boron (especially 10B isotope) superior to all other elements for neutron absorption. Most promising option for space applications as structural shielding material when combined with a polyethylene matrix |

| Electrical |

| BNNT |

|

| Both | ||

| CNT, Cu-CNT or Al-CNT | ||

| Piezoelectric | Structural health monitoring Energy generation Active control of structures | BNNT | Small strains can generate voltages or applying a voltage can give rise to strains |