Boronite was founded in 2015 by Materials Scientists Dr. David Lashmore (CEO) and Dr. Pavel Bystricky (CTO) and by Ivka Kalus (CFO). The company is wholly-owned by its employees. Our focus is the development of advanced boron nitride nanotube (BNNT) materials and derivative products, under sponsorship of the Department of Defense. We are also involved in the development of carbon nanotube (CNT) advanced materials, composites, and fabrics, including CNT yarn of several different chiralities and lengths.

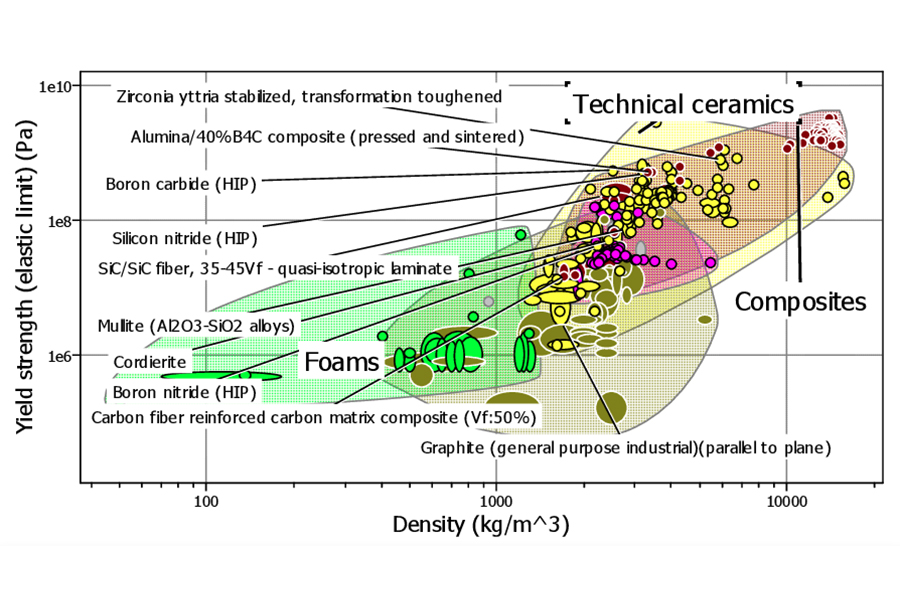

The BNNT material has breaking strengths on the order of ~60 GPa. Interestingly, the adhesion between boron nitride nanotubes appears to be many times higher than between carbon nanotubes, which is attributable to the corrugated surface of BNNTs and to partial ionic bonding. CNTs and BNNTs are isostructural and isoelectronic but their electrical properties are very different: CNTs are semiconductor / metallic conductors (depending on chirality) whereas BNNTs are insulators with a very high bandgap on the order of 5.9 eV. BNNTs and CNTs have similar thermal conductivity, with individual nanotube conductivity of ~800 W/m.K (compared to copper: 380 W/m.K, BeO: 280 W/m.K, and AlN: 150 W/m.K). These properties make BNNTs ideal candidates for thermal management applications where heat can be ducted away from a source especially in a PC board or even in a ceramic composite. When exposed to high-energy, high-frequency radiation the circuit board will remain cooler thereby improving component performance.

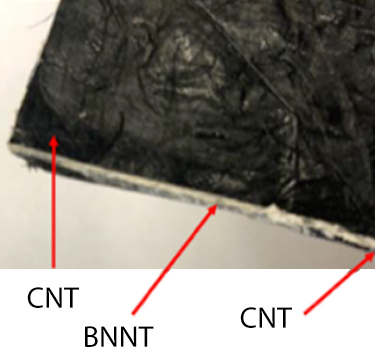

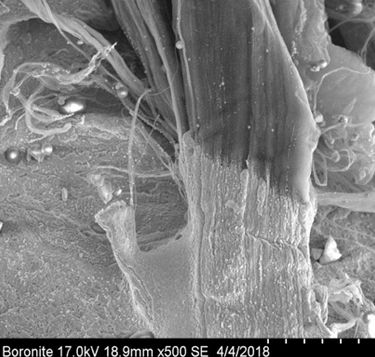

The “low temperature” CVD process we use to synthesize the material is different from other BNNT traditional processing methods. The material comes out of the furnace at a high yield and appears as fluffy cotton. It can be flattened to a sheet and formatted into a sandwich structure with CNT sheet which provides strength as well as a Faraday cage. These kinds of structures have value for flexible neutron barriers and other radiation protection in space.

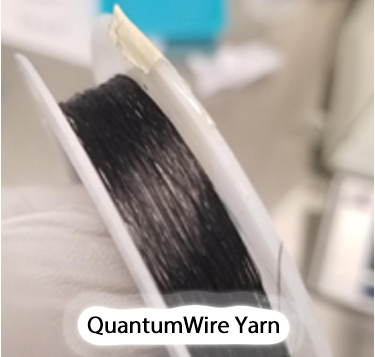

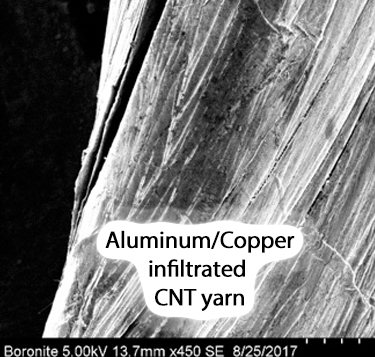

The carbon nanotube CNT growth processes make use of proprietary fuels and processing configurations. We make (1) a metallic CNT yarn in which the nanotubes are predominantly of metallic chirality (patent pending), and (2) a CNT composite wire in which the continuous CNT network is infiltrated with an aluminum or copper matrix designed to wet the nanotubes (SuperWire). This product is also patent pending. We also produce a CNT-based IR emitter described below along with other products made from our two main product platforms.

Table of Potential Products

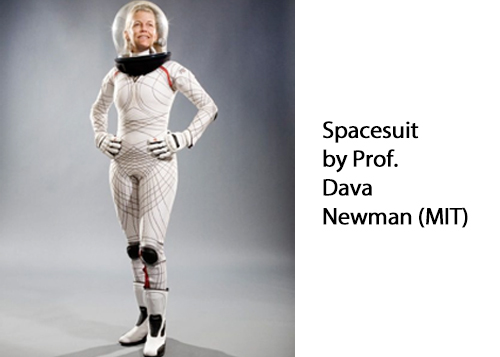

BNNT Mats: Boron nitride nanotube mats are made by collecting the material on a flat surface and pressing it into a flat non-woven textile. CNT non-woven sheets can be bonded to the BNNTs as can PE sheets. The BNNT mats may be able to hold 20% by weight of hydrogen. Properties: These materials contain boron, which is better than any other element at absorbing neutron radiation. It is possible to bond a CNT sheet on the top and bottom. This flexible structure can then be formed into a form fitting space suit that effectively blocks high energy electrons as well as neutrons. It can also be incorporated into body armor that will provide protection from a variety of threats. Sponsors: Department of Defense as well as several aerospace companies. Suggested Customers/Applications: space suit makers and users, Prime contractors, wire and cable makers, radiation protection clothing manufacturers, rad hard electronics, electronics packaging – thermal transport in printed circuit boards. X-ray transparent panels and composites, dielectric composites. IP: Trade secrets. |    |

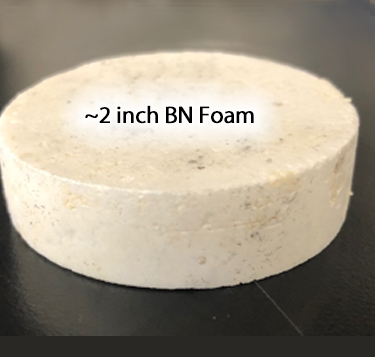

BN Foams: These foams are produced by pyrolysis of a borazine derivative product. Hydrogen released during curing creates the porosity. The foams are castable in almost any shape and size and the porosity may be controlled. The cast foams may be reinforced with BNNT or BN powder to create a nearly fully dense composite. They can be made reticulated. Properties: Able to withstand temperatures ~ 1500 °C for an undetermined time in a reducing flame in air. Other properties are still being determined (dielectric constant in the GHz region, insertion loss, transmission, complex index of refraction, thermal conductivity, strength). Sponsors: Department of Defense and a Prime contractor. Suggested Customers/Applications: Prime contractors/Radar windows that have to withstand high temperatures. IP: Trade secrets |   |

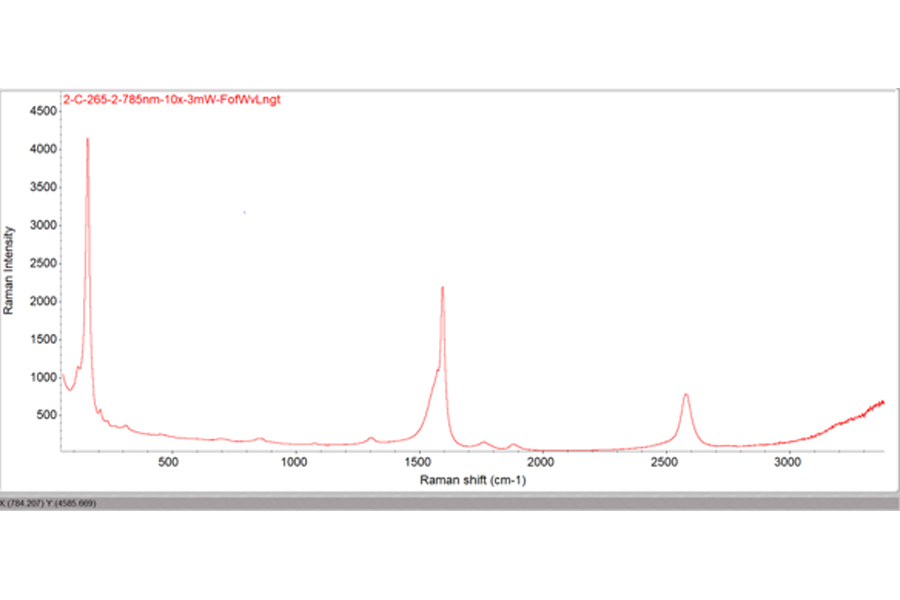

Quantum Wire: This material is a CNT yarn with predominantly metallic nanotubes produced in our reactors. It is made by a proprietary process and confirmed by TEM and by Raman spectroscopy. Properties: The conductivity is a function of the tube alignment in the yarn, which is still under development. The tube conductivity is expected to be exceptional as the bandgap is 0. Sponsors: Department of Defense. Suggested Customers/Applications: Textile-robust wiring, wire used at high temperatures, wire transparent to most x-rays, wire used under stress, extremely thin wire, fatigue proof wiring. IP: Patent pending, trade secrets. |   |

Carbon Nanotube Superwire: Metal matrix composite wire with high volume fraction of CNT reinforcement made by a pultrusion process which allows infiltration of a continuous CNT yarn. Properties: High conductivity, very high ampacity, light weight, much stronger than copper or aluminum. Sponsors: Department of Defense Suggested Customers/Applications: (1): high current applications, (2) applications where electromigration is a problem, (3) applications where weight of the current carrying cable is a problem, (4) applications where fatigue is an issue. IP: Patent pending. |   |

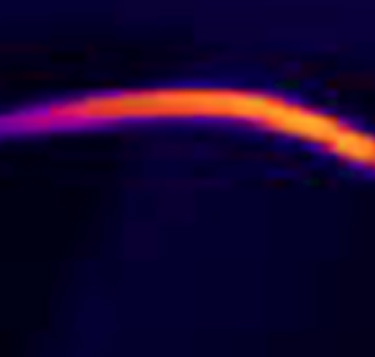

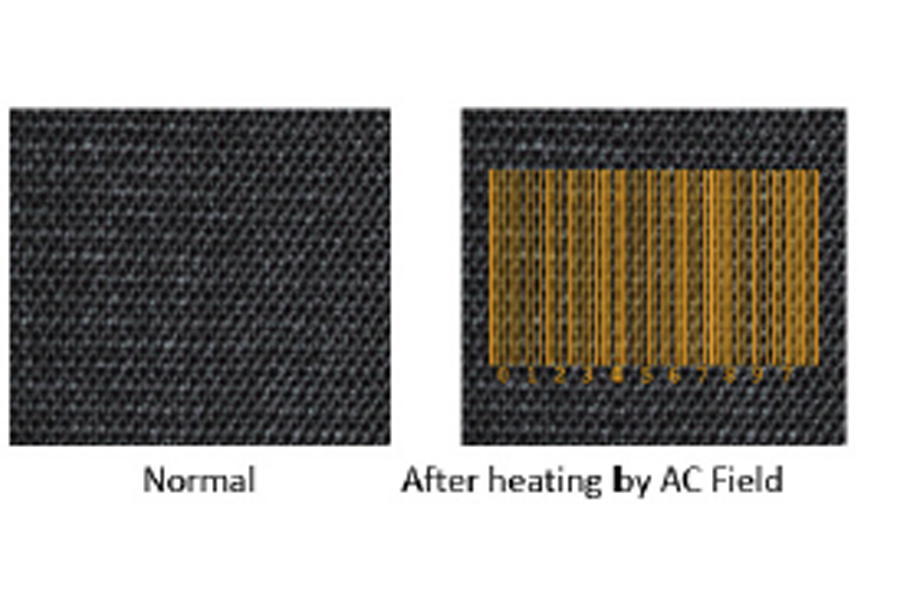

Carbon Nanotube IR emitters: The very low specific heat of CNTs allows them to heat up and cool down very quickly. The cycle frequency may be as high as 100 kHz. This opens up the possibility of creating IR emitters in the form of bar codes whose message can be encrypted in frequency, in position, in polarization and in temperature differences. Properties: high turn-on/off frequencies. Sponsors: (none). Suggested Customers/Applications: Embedded textiles, embedded high value-added products, friend or foe ID, remote control of drones, anticounterfeiting active or passive. IP: Patented. |   |

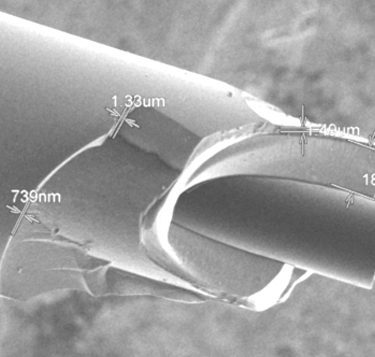

BN coated SiC fibers: ~ 1-micron coating of BN on SiC fibers used in composite turbine blades to increase fracture toughness and reduce oxidation at extreme temperatures. Properties: Very uniform crack free coatings on continuous SiC fiber. Sponsors: Specialty Materials and potentially a jet engine company. Suggested Customers/Applications: Aircraft engines turbine blades in the hot stage of the motor, new HT fibers such as BN fibers on a CNT core, applications where a structure must survive exposure to very hot materials or gases. IP: Trade secrets. |  |